Eastman Shuangwei Fibers Co., Ltd. mainly produces cellulose diacetate tow for cigarette. The design scale of the first phase of the project is 30000 tons per year, covering an area of 177.7 mu, and the total investment estimate is nearly 1.6 billion yuan.

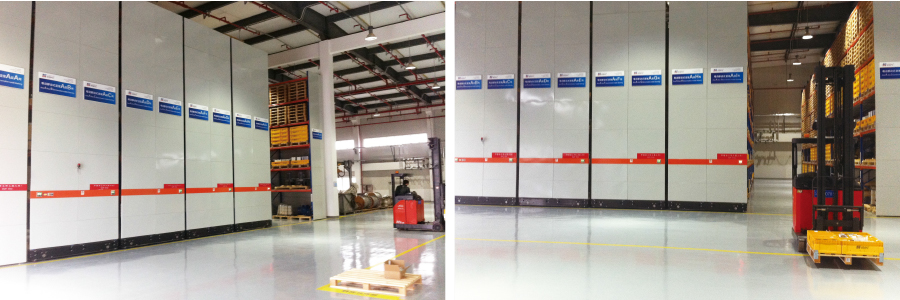

The height of the equipment spare parts warehouse is 8500mm, the planning area is 315 ㎡, and the heavy spare parts storage space needs 1500. The early planning and design adopts AS/RS automated three-dimensional warehouse, with 2 lanes. Because the height of the AS/RS sky rail lifting beam needs to occupy part of the space, the number of shelf layers can only be 6, and only 1200 heavy spare parts storage spaces can be designed, which cannot meet the requirements of customers. After actual research, our company communicated with customers that we used electric mobile racks with forward moving forklifts, bound WMS software for spare parts storage and retrieval. There were 1534 heavy spare parts storage spaces, and designed other forms of racks for customers. For small precision spare parts, we used two full-automatic vertical rotating containers for storage. For small spare parts, non-standard turnover boxes and other products, the cost has decreased by 50% year-on-year, the construction cycle has been shortened by 50%, and the design function is basically the same as that of AS/RS. Customers very much agree with this scheme.

After the customer's investigation of our similar projects and the company's strength, the customer is very relieved to hand over the project to us for construction. The project was started on December 19, 2011, and began commissioning in February and March 2012. At present, the project is running well, and the customer gives it high praise.

QQ: 404977441

手机:+86 15255128828

电话: 0551-63674818

邮箱: export@ahhuayide.com

地址:Building A, Linbin Yuan, NO 5116 Huizhou Avenue, Hefei, China.